Electrical Earthing is the process of transferring the immediate electrical discharge directly to the Earth. It involves establishing a direct conductive path between an electrical circuit or equipment and the Earth’s conductive surface through low-resistance wires. Proper earthing is essential for various reasons, primarily ensuring safety, enhancing the performance of electrical systems, and protecting equipment and individuals from electrical faults and lightning strikes.

Earthing is a fundamental practice in the field of electrical engineering. Its importance cannot be overstated, as it plays a central role in ensuring the safety of individuals, the protection of equipment, and the stability of electrical and electronic systems. Following relevant standards and regulations, proper earthing practices must always be followed to create a safe and efficient electrical environment.

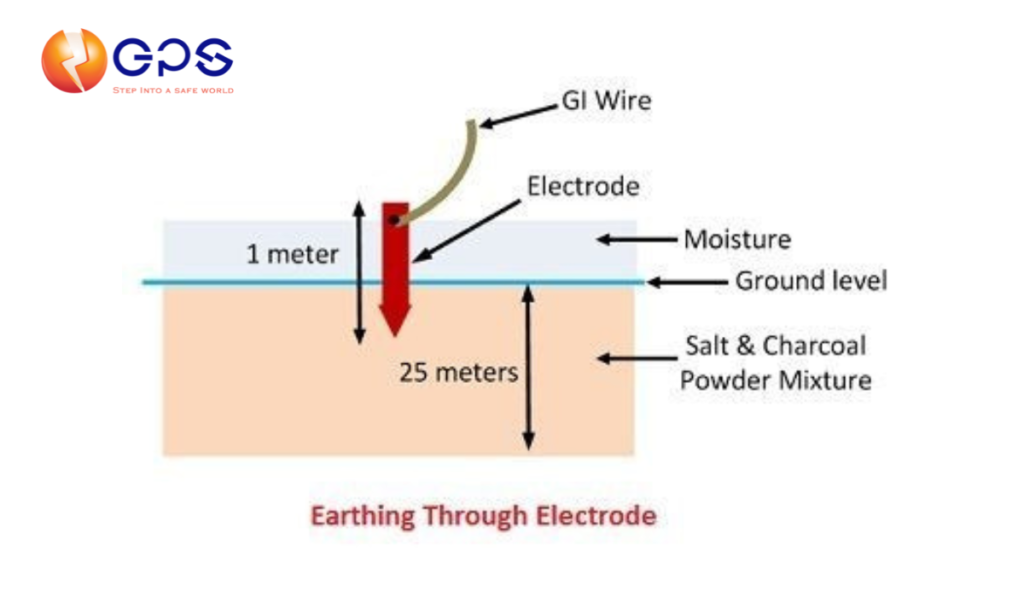

To ensure safety, grounding can be established by connecting the electrical appliance to earthing systems or electrodes placed near or below the ground level.

An electrode or earthing mat equipped with a flat iron riser is installed below ground level to facilitate the connection of all non-current-carrying metallic parts of the equipment.

The image below depicts the earthing system incorporated into an electrical system.

Earthing provides a low-resistance path for fault currents to flow safely into the ground. This prevents electrical shocks and protects individuals from injuries.

Earthing helps discharge excess current during short circuits, preventing damage to electrical appliances, devices, and circuits.

Proper earthing is crucial in lightning protection systems. Lightning conductors are connected to the ground to direct the lightning strike’s energy safely into the Earth, protecting buildings and their occupants.

Earthing helps stabilise voltage levels in electrical systems, ensuring consistent and reliable operation of appliances and devices.

In electronic circuits, grounding helps reduce electromagnetic interference and noise, ensuring clean and accurate signal transmission.

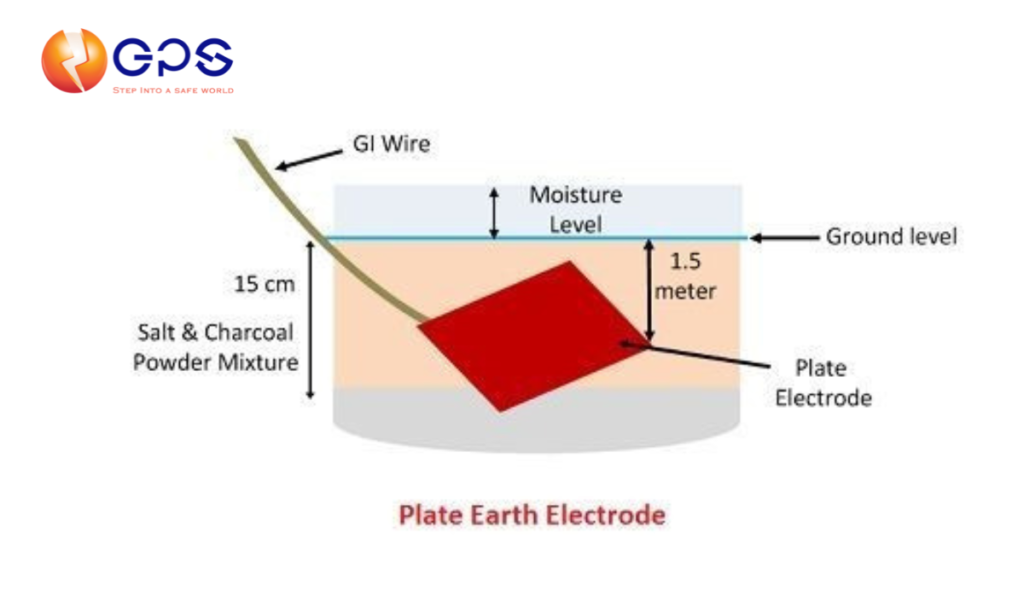

Plate earthing connects electrical equipment or systems to the ground using a metal plate buried in the earth. This metal plate, typically made of copper or galvanized iron, serves as an electrode and provides a low-resistance path for fault currents and surges to safely dissipate into the ground.

The metal plate, usually made of copper or iron, buried vertically in the ground. The plate size depends on the current to be carried and the soil resistivity.

A metal conductor (usually copper) connects the electrical equipment or system to the earthing plate. It provides a pathway for the fault current to flow into the ground.

The earthing plate and conductor combination form the earthing electrode, ensuring the electrical system is effectively grounded.

Prevents electric shocks by providing a low-resistance path for fault currents to flow into the ground, minimizing the risk to people and animals.

By diverting fault currents into the ground, plate earthing protects electrical equipment and appliances from damage during electrical faults.

Plate earthing is an essential component of lightning protection systems, providing a safe path for lightning strikes to dissipate into the ground, protecting structures and electrical systems.

Plate earthing stabilizes electrical systems by maintaining a constant reference potential, ensuring proper equipment functioning, and preventing voltage fluctuations.

Electrical codes and standards often mandate proper earthing to ensure the safety and reliability of electrical installations. Plate earthing systems must comply with these regulations.

Plate earthing is widely used in various residential, commercial, and industrial applications to provide a safe and stable grounding system for electrical installations. Proper installation, design, and maintenance are essential to ensure the effectiveness of the plate earthing system.

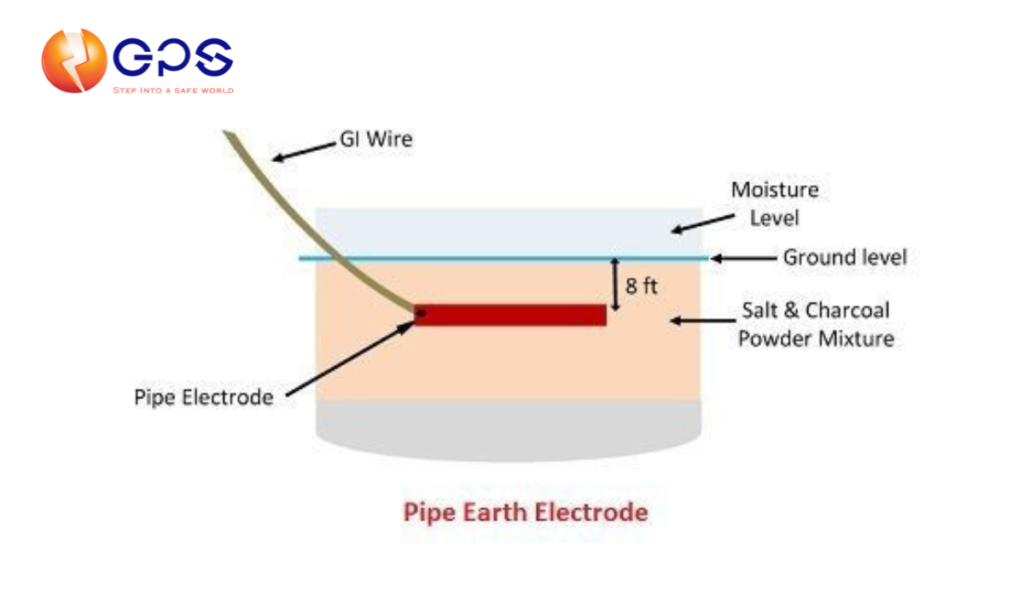

Pipe earthing, also known as electrode earthing, is a method of grounding electrical systems where a galvanized iron or copper pipe is used as an electrode to establish a connection with the earth. This type of earthing system involves inserting a metal pipe vertically into the ground. The pipe, made of galvanized iron or copper, acts as a conductor to provide a low-resistance path for fault currents to safely dissipate into the earth.

A metal pipe, usually made of galvanized iron or copper, is buried vertically in the ground to serve as an electrode. The size and length of the pipe depend on the current to be carried and

the soil resistivity.

A metal conductor (often copper) connects the electrical system to the earthing pipe, allowing fault currents to flow into the ground.

The earthing pipe and earthing conductor combination forms the earthing electrode, ensuring the electrical system is effectively grounded.

Pipe earthing prevents electric shocks by providing a low-resistance path for fault currents to flow into the ground, minimizing the risk to people and animals.

By diverting fault currents into the ground, pipe earthing protects electrical equipment and appliances from damage during electrical faults.

Pipe earthing is an essential component of lightning protection systems, offering a safe path for lightning strikes to dissipate into the ground, protecting structures and electrical systems.

Pipe earthing stabilizes electrical systems by maintaining a constant reference potential, ensuring proper equipment functioning, and preventing voltage fluctuations.

Electrical codes and standards often mandate proper earthing to ensure the safety and reliability of electrical installations. Pipe earthing systems must comply with these regulations.

Pipe earthing is commonly used in various residential, commercial, and industrial applications to provide a safe and stable grounding system for electrical installations. Proper installation, design, and maintenance are essential to ensure the effectiveness of the pipe earthing system.

Rod earthing, also known as ground rod or electrode earthing, is a method of grounding electrical systems where a metal rod is driven vertically into the ground to establish a connection with the earth. This earthing system involves inserting a metal rod, often made of copper or galvanized iron, into the soil. The rod serves as a conductor to provide a low-resistance path for fault currents and surges to safely dissipate into the earth.

A metal rod, typically made of copper or galvanized iron, driven vertically into the ground to act as an electrode. The size and length of the rod depend on the current to be carried and the soil resistivity.

A metal conductor (usually copper) connects the electrical system to the earthing rod, allowing fault currents to flow into the ground.

The earthing rod and earthing conductor combination forms the earthing electrode, ensuring the electrical system is effectively grounded.

Rod earthing prevents electric shocks by providing a low-resistance path for fault currents to flow into the ground, minimizing the risk to people and animals.

By diverting fault currents into the ground, rod earthing protects electrical equipment and appliances from damage during electrical faults.

Rod earthing is an essential component of lightning protection systems, offering a safe path for lightning strikes to dissipate into the ground, protecting structures and electrical systems.

Rod earthing stabilizes electrical systems by maintaining a constant reference potential, ensuring proper equipment functioning, and preventing voltage fluctuations.

Electrical codes and standards often mandate proper earthing to ensure the safety and reliability of electrical installations. Rod earthing systems must comply with these regulations.

Rod earthing is widely used in various residential, commercial, and industrial applications to provide a safe and stable grounding system for electrical installations. Proper installation, design, and maintenance are essential to ensure the effectiveness of the rod earthing system.

Strip earthing, also known as strip electrode earthing, is a method of grounding electrical systems where a wide metal strip is buried horizontally in a trench. This type of earthing system involves laying a flat, wide metal strip, often made of copper or galvanized iron, in a shallow trench that is then backfilled with soil, ensuring good contact with the earth.

A wide metal strip, typically made of copper or galvanized iron, laid horizontally in a shallow trench in the ground to act as an electrode. The strip provides a large surface area for effective grounding.

A metal conductor (usually copper) connects the electrical system to the earthing strip, allowing fault currents to flow into the ground.

The earthing strip and conductor combination form the earthing electrode, ensuring the electrical system is effectively grounded.

Strip earthing prevents electric shocks by providing a low-resistance path for fault currents to flow into the ground, minimizing the risk to people and animals.

By diverting fault currents into the ground, strip earthing protects electrical equipment and appliances from damage during electrical faults.

Strip earthing stabilizes electrical systems by maintaining a constant reference potential, ensuring proper equipment functioning, and preventing voltage fluctuations.

Electrical codes and standards often mandate proper earthing to ensure the safety and reliability of electrical installations. Strip earthing systems must comply with these regulations.

Strip earthing is suitable for areas where traditional vertical rod earthing, such as rocky terrain or locations with limited space, may need to be more practical. Proper installation, design, and maintenance are essential to ensure the effectiveness of the strip earthing system.

Earthing through water mains, is a method of grounding electrical systems by utilizing the metal water pipes that are part of a building’s plumbing network. In this system, a connection is made between the electrical installation and the metal water pipes, which serve as an earthing electrode. The earth connection is established via the water distribution system, utilizing the conductive properties of the metal pipes to provide a path for fault currents to safely dissipate into the ground.

The existing metal pipes within a building's plumbing system, usually made of copper or galvanized iron, serve as the earthing electrode.

A metal conductor (typically copper) connects the electrical system to the metal water pipes, providing a pathway for fault currents to flow into the ground through the plumbing network.

Water pipe earthing prevents electric shocks by providing a low-resistance path for fault currents to flow into the ground, minimizing the risk to people and animals.

By diverting fault currents into the ground, water pipe earthing protects electrical equipment and appliances from damage during electrical faults.

Electrical codes and standards often allow using metal water pipes as an earthing electrode, provided specific requirements and

regulations are met.

The metal pipes must be continuous and electrically conductive. Any non-conductive sections or insulating joints should be bridged appropriately to maintain the effectiveness of the earthing system.

Corrosion-resistant clamps and connectors ensure a secure and long-lasting connection between the earthing conductor and the water pipes.

Water pipe earthing is a practical method, especially in buildings where metal water pipes are readily available and compliant with relevant standards. However, it’s essential to adhere to local regulations and guidelines to ensure the proper installation and safety of the earthing system.

An earthing or grounding mat connects the human body to the Earth’s natural electric charge. It typically consists of a conductive material connected to the ground or a grounding outlet, such as carbon-infused rubber or conductive fabric. The purpose of an earthing mat is to allow people to make direct skin contact with the conductive surface, which establishes an electrical connection between the body and the Earth.

Earthing mats help dissipate excess static electricity from the body, reducing the risk of electrostatic discharge (ESD) and providing a safer environment for working with sensitive electronic components.

Some proponents of earthing mats claim potential health benefits, suggesting that direct contact with the Earth's natural electric charge may reduce inflammation, improve sleep, and promote overall well-being. However, scientific evidence supporting these claims still needs to be more conclusive.

Earthing mats are sometimes used to neutralize electromagnetic fields (EMFs) by grounding the body, which may reduce the exposure to EMFs emitted by electronic devices.

In office settings, earthing mats are often placed under desks, allowing individuals to rest their bare feet or hands on the mat while working to promote grounding.

Some earthing mats are designed to be placed on the bed, allowing individuals to sleep with direct skin contact with the conductive surface.

Mobile versions of earthing mats can be rolled up and taken with you, allowing grounding while traveling or spending time outdoors.

It’s important to note that while many people find earthing practices beneficial, the scientific community is still studying the potential health effects rigorously. As with any health-related product, individuals should consult healthcare professionals and rely on scientifically verified information before making health-related decisions.

To prevent electrical hazards, earthing is essential for all electrical outlets and appliances.

Proper earthing is crucial for heavy machinery, ensuring both personnel safety and the protection of expensive equipment.

Grounding provides signal quality, prevents electrical interference, and protects equipment.

Grounding is a fundamental part of lightning protection systems, enabling the safe dissipation of lightning energy into the Earth.

Soil conductivity impacts efficiency. Good conductivity favors plate or rod earthing, while poor conductivity may require extensive systems like grounding grids.

Available space influences the choice. Strip earthing suits small areas, while larger spaces may accommodate other systems.

Specific electrical system needs play a role. Sensitive electronics may demand robust grounding like grounding grids.

Expected fault currents affect system selection. Larger currents may require more substantial grounding.

Local codes and standards dictate system requirements for safety and reliability.

Moisture levels and temperature variations affect soil resistivity, influencing system efficiency.

In summary, engineers consider these factors to design a grounding system that ensures safe and efficient electrical operation for a specific installation.

GPS INDIA TECHVENTURES PVT LTD

1298/17, Ground Floor, Sector 17

Faridabad, Haryana – 121 002, INDIA

Marketing Office: Bengaluru, Chennai, Ghaziabad, Kolkata

Works 1: Kanniyakumari, Tamil Nadu

Works 2: Faridabad, Haryana

© 2025 GPS . All rights reserved | Privacy Policy Designed & Developed by Thinksmiths Software Services Pvt. Ltd.